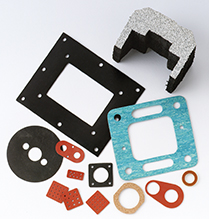

DIE CUTTING AND STAMPING

The Howard J. Moore Company got its start in 1945 with the purchase of our first die cutting press. Over the years our capabilities have grown, but our core attention to quality, speed and cost has remained unchanged.

The Howard J. Moore Company got its start in 1945 with the purchase of our first die cutting press. Over the years our capabilities have grown, but our core attention to quality, speed and cost has remained unchanged.

Our experience in the industry helps make our facility the perfect choice to meet your business’s Die Cutting and Stamping needs. We make our tools and dies in house and operate two dozen automated, and manual presses for die cutting, punching, stamping, and forming. Our fastest presses have 5,000 strokes per hour capacity with automatic material feeds, allowing us to affordably handle high volume jobs with ease.

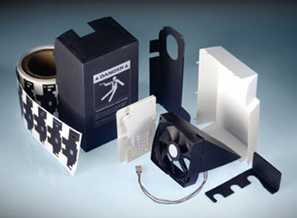

T oday our primary customers for die cut and stamped parts are in the electronicsand defense industries, with the majority of our products being used for electrical and thermal insulation, EMI shielding, and gasketing. We keep an extensive material inventory including Nomex, Kapton, Formex, Mylar, PTFE film, phenolic sheets, a wide assortment of Silicone and Neoprene Rubbers, adhesive backed materials, and much more.

oday our primary customers for die cut and stamped parts are in the electronicsand defense industries, with the majority of our products being used for electrical and thermal insulation, EMI shielding, and gasketing. We keep an extensive material inventory including Nomex, Kapton, Formex, Mylar, PTFE film, phenolic sheets, a wide assortment of Silicone and Neoprene Rubbers, adhesive backed materials, and much more.