Thermo-Plastics

High Performance Plastics

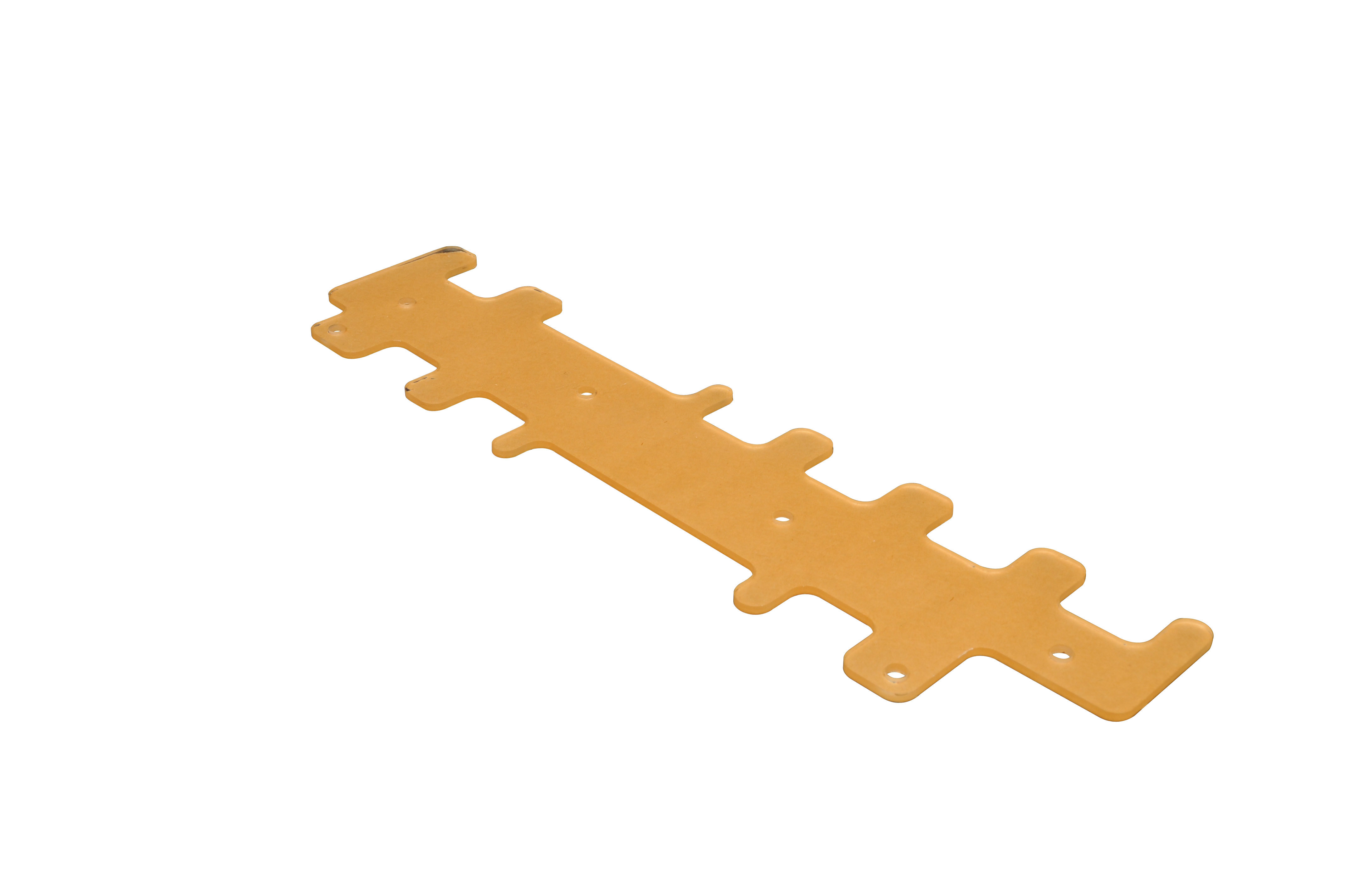

Ultem® (Polyetherimide, PEI) – (Data Sheet) is a high-performance amorphous thermoplastic known for its exceptional strength, dimensional stability, and resistance to heat and flame. It offers continuous use temperatures up to 340°F (170°C), with excellent dielectric properties and inherent flame retardancy (UL 94 V-0 without additives). Ultem retains its strength and stiffness at elevated temperatures, making it a popular choice for demanding structural and electrical applications.

Ultem is commonly used in aerospace, automotive, medical, and electronics industries for parts such as insulating components, manifolds, brackets, housings, and semiconductor fixtures. It can withstand repeated autoclaving, making it suitable for reusable medical and dental devices. Ultem is available in unfilled, glass-filled, and custom grades for enhanced mechanical performance and meets ASTM D5205

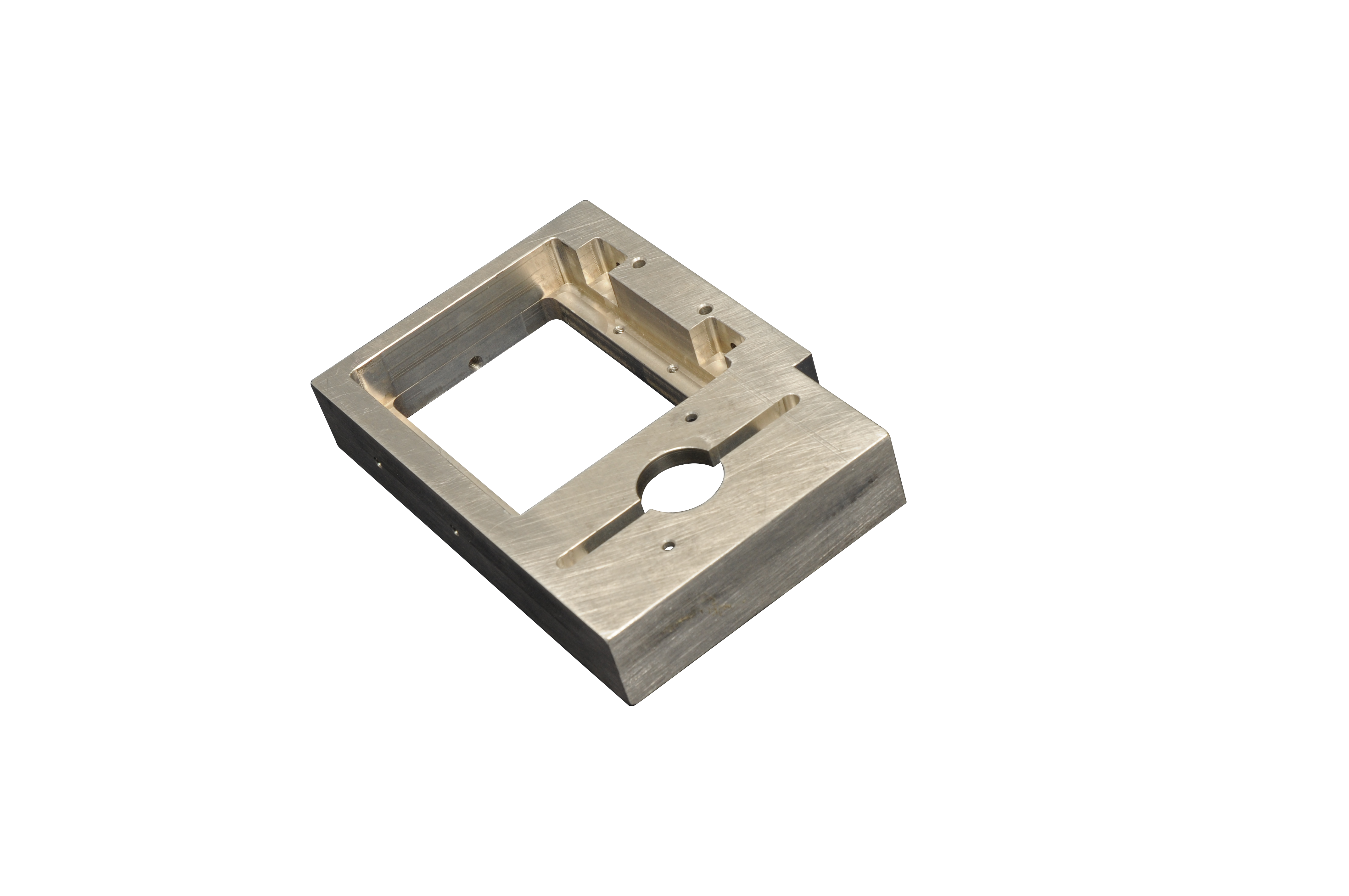

Polyetheretherketone (PEEK) – (Tech Sheet) (GF30 Tech Sheet) is a high-performance, semi-crystalline thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability. It performs reliably in extreme environments, maintaining its properties at continuous use temperatures up to 480°F (250°C). PEEK exhibits excellent wear resistance, low moisture absorption, and superior dimensional stability, making it ideal for demanding aerospace, medical, and industrial applications.

Common uses include bushings, seals, electrical connectors, semiconductor components, medical implants, and high-temperature structural parts. PEEK is available in unfilled, glass-filled, and carbon-filled grades to enhance strength, stiffness, or conductivity. It is FDA compliant in its virgin form and is also resistant to high-pressure steam, making it suitable for autoclaving and repeated sterilization.

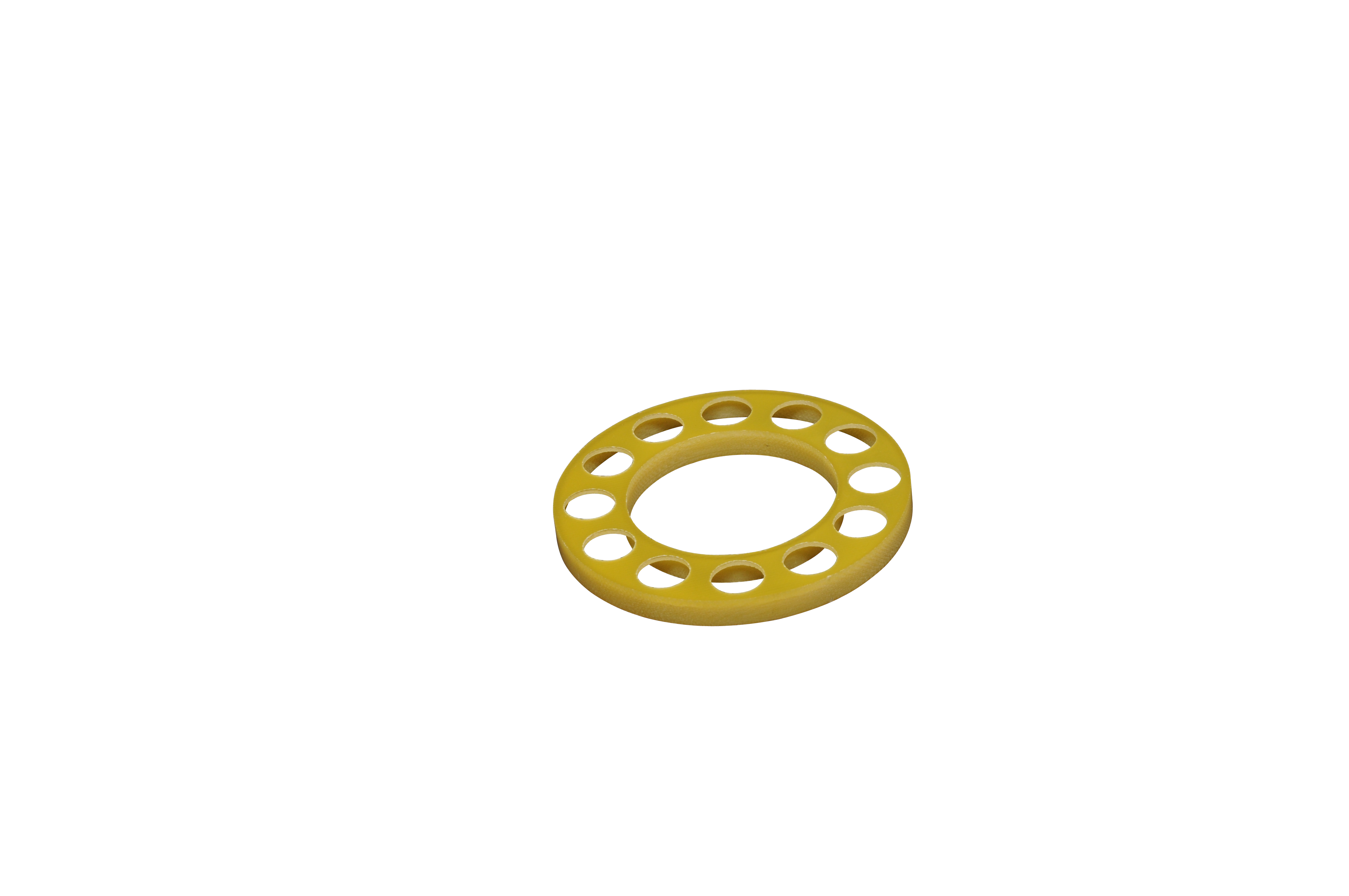

Torlon® (Polyamide-imide, PAI) is an ultra-high-performance thermoplastic known for its outstanding mechanical strength, dimensional stability, and thermal resistance. It offers some of the highest strength and stiffness among unreinforced thermoplastics, even at elevated temperatures up to 500°F (260°C). Torlon exhibits excellent wear resistance, low creep, and outstanding chemical resistance, making it suitable for severe service conditions.

Common applications include aerospace and automotive components, high-load bearings, wear rings, electrical insulators, and precision-machined parts in high-heat environments. Torlon is available in several formulations, including glass-fiber reinforced, carbon-fiber reinforced, and bearing grades with PTFE or graphite for enhanced wear and friction performance. Due to its high-performance nature, Torlon is typically machined from rod or plate and is not easily injection molded in small-scale settings. Torlon meets ASTM D5204

Polysulfone (PSU) is a tough, high-temperature thermoplastic known for its excellent mechanical strength, dimensional stability, and resistance to hot water and steam. It maintains its strength and rigidity over a wide temperature range and offers outstanding hydrolytic stability, making it ideal for repeated steam sterilization. Polysulfone also has good electrical insulating properties and is resistant to many acids, bases, and detergents.

Common applications include medical and laboratory equipment, sterilizable components, manifolds, filtration housings, and food processing parts. It is frequently used as a transparent alternative to metals or lower-grade plastics in high-performance applications. Though naturally amber-tinted and not UV-stable for prolonged outdoor use, it is highly valued in environments requiring repeated cleaning, autoclaving, or exposure to hot aqueous solutions.

Vespel® (Polyimide, PI)– (Data Sheet) is a premium high-performance thermoplastic made by DuPont that is renowned for its unmatched combination of heat resistance, low wear, chemical stability, and mechanical strength. Unlike most plastics, Vespel can operate continuously at temperatures up to 550°F (288°C) and intermittently beyond 900°F (482°C) without significant loss of properties. It is exceptionally dimensionally stable, making it ideal for precision components in extreme environments.

Vespel is commonly used in aerospace, semiconductor, automotive, and industrial applications where conventional plastics would fail—such as seals, bearings, bushings, valve seats, wear components, and thermal insulators. It is available in unfilled and filled grades, including graphite and PTFE-filled versions for enhanced wear and friction performance. Vespel is typically machined from rod or plaque and is known for producing clean, burr-free parts even at tight tolerances.

Engineering Plastics

Delrin® (Acetal Homopolymer) – (Spec Sheet)

Delrin® (Acetal Homopolymer) – (Spec Sheet)

Delrin®, also known generically as acetal homopolymer, is a versatile engineering thermoplastic known for its exceptional strength, stiffness, and dimensional stability. Characterized by its low friction, excellent wear resistance, and ease of machining, Delrin® is ideal for precision components requiring tight tolerances and smooth surfaces. Its inherent moisture resistance and minimal moisture absorption make it highly suitable for use in damp or wet environments. Delrin® is available in various grades, including standard, glass-filled, PTFE-filled, and enhanced toughness grades, each tailored to specific performance requirements such as increased strength, reduced friction, or improved impact resistance.

Common applications for Delrin® include gears, bearings, bushings, rollers, valves, electrical components, and various mechanical parts requiring reliable performance and durability. Due to its combination of strength, rigidity, and machinability, Delrin® is frequently chosen for custom-fabricated parts across industries such as automotive, aerospace, electronics, medical equipment, and industrial manufacturing.

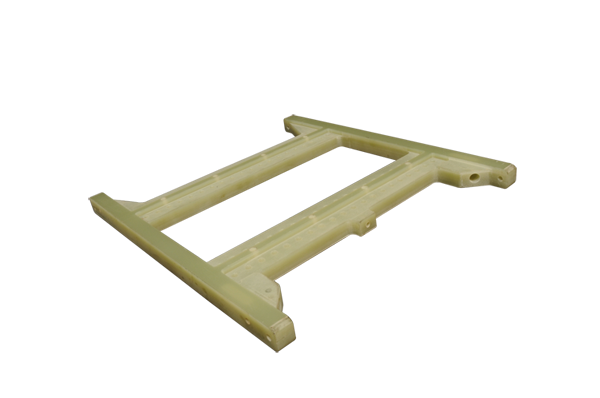

Nylon (Polyamide) – (Spec Sheet) is a versatile and durable engineering thermoplastic known for its excellent mechanical strength, wear resistance, and low friction properties. It is commonly used in both industrial and consumer applications due to its toughness, chemical resistance, and good thermal stability. Nylon is available in several types, with Nylon 6 and Nylon 6/6 being the most commonly used in fabrication and machining.

Nylon is often used in applications such as bushings, gears, rollers, bearings, wear pads, insulators, and structural components. It performs well in both dry and lubricated environments and is frequently selected as a lightweight metal replacement in moving parts. Certain grades are filled with glass or molybdenum disulfide (MoS₂) to enhance stiffness (i.e. Nylatron), dimensional stability, or wear properties. Commonly used specifications for Nylon include ASTM D4066, and ASTM D6779,

Polycarbonate (PC) also known by it’s common trade names of Lexan®, Makrolon®, & Tuffak®, is a strong, lightweight, and transparent thermoplastic known for its exceptional impact resistance and optical clarity. It is often chosen as an alternative to glass or acrylic in demanding applications where toughness and clarity are critical. Polycarbonate also offers good dimensional stability, heat resistance, and electrical insulating properties, making it suitable for a wide range of uses in both industrial and consumer products.

Polycarbonate (PC) also known by it’s common trade names of Lexan®, Makrolon®, & Tuffak®, is a strong, lightweight, and transparent thermoplastic known for its exceptional impact resistance and optical clarity. It is often chosen as an alternative to glass or acrylic in demanding applications where toughness and clarity are critical. Polycarbonate also offers good dimensional stability, heat resistance, and electrical insulating properties, making it suitable for a wide range of uses in both industrial and consumer products.

Common applications include safety glazing, machine guards, lenses, light diffusers, medical devices, and electrical housings. It is easy to machine and fabricate, and can be thermoformed or cold bent without cracking. While not as scratch-resistant as acrylic, polycarbonate can be coated to enhance surface hardness. Flame-retardant and FDA-compliant grades are also available for specialized applications.

The Howard J. Moore Company stocks multiple grades and thicknesses of Polycarbonate and can easy Die Cut sheets up to 1/16” thick and machine Polycarbonate plate and run. Polycarbonate can be easily printed on for cosmetic applications.

PTFE (Polytetrafluoroethylene)

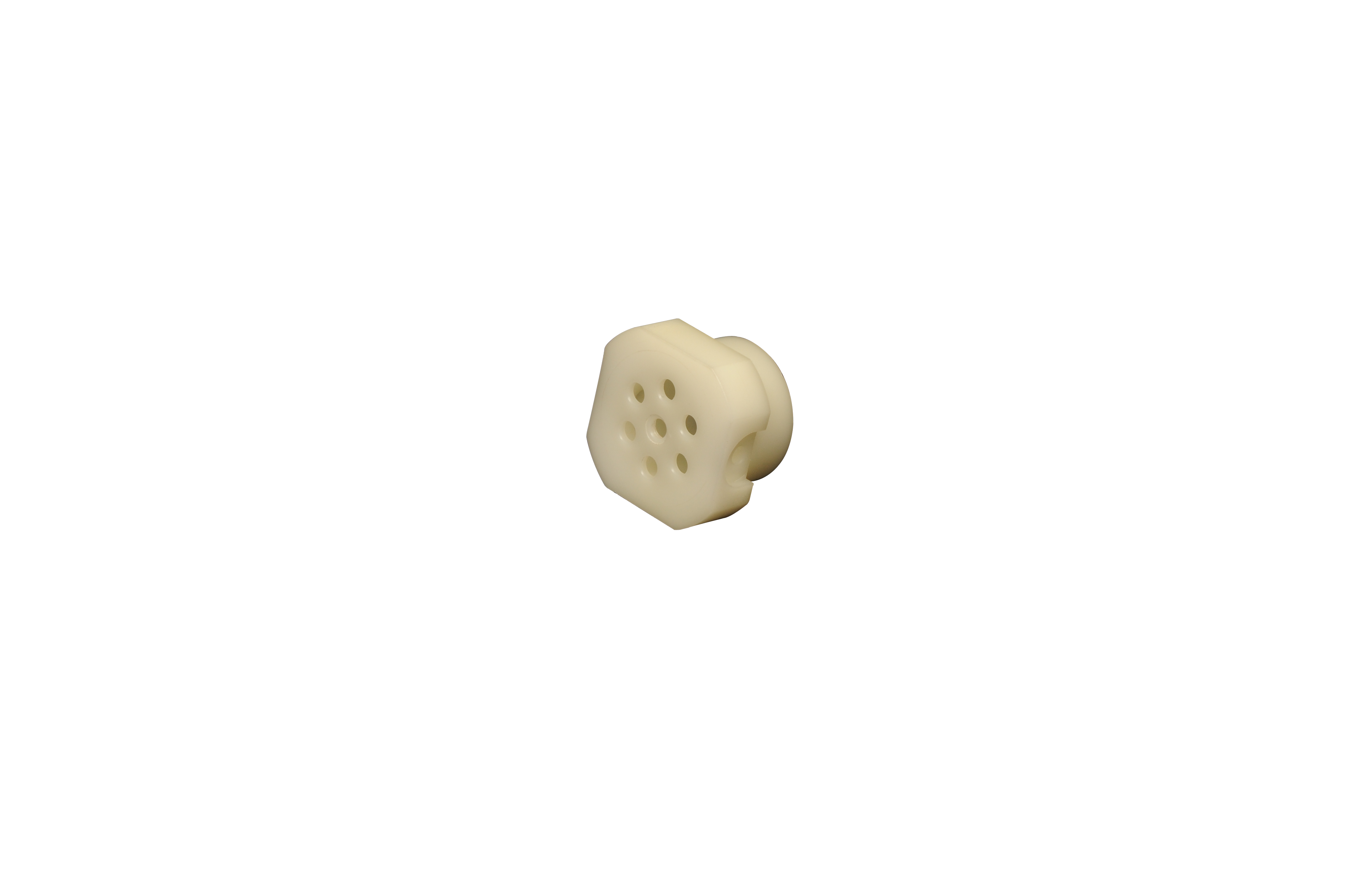

PTFE, commonly known by the brand name Teflon®, is a high-performance fluoropolymer noted for its exceptional chemical resistance, non-stick properties, and wide temperature tolerance. With one of the lowest coefficients of friction among solid materials, PTFE is an ideal choice for applications involving sliding or moving parts, where friction and wear must be minimized. Its excellent insulating properties and outstanding resistance to moisture and virtually all chemicals make it particularly suitable for harsh environments. Common ASTM and AMS specifications for PTFE include ASTM D1710, ASTM D3294, ASTM D4894, AMS 3651, AMS 3652, and AMS 3660, ensuring compliance with precise industry standards.

PTFE is available in several grades, including virgin (unfilled), glass-filled, carbon-filled, bronze-filled, and graphite-filled grades. These specialized formulations offer improved properties such as enhanced dimensional stability, increased wear resistance, greater compressive strength, and improved thermal conductivity. Typical applications include seals, gaskets, bearings, bushings, valve seats, electrical insulation, and components for chemical processing equipment across industries like chemical manufacturing, pharmaceuticals, food processing, electronics, and aerospace.

Acrylic (Polymethyl Methacrylate, PMMA) commonly known by its trade name of Plexiglas® is a transparent thermoplastic known for its excellent optical clarity, weather resistance, and aesthetic appeal. Often used as a lightweight and shatter-resistant alternative to glass, acrylic is easy to fabricate, polish, and thermoform, making it ideal for both functional and decorative applications. It is available in both cast and extruded forms, with cast acrylic offering superior optical quality and machinability. Acrylic can also be easily laser cut, a process capable of cutting complex geometries and leaving a flame polished edge.

Typical uses include signage, display cases, windows, lighting diffusers and medical & test equipment. Acrylic is more scratch-resistant than polycarbonate, though it is less impact-resistant. It performs well in outdoor environments due to its UV stability and resistance to yellowing over time. It’s ease of fabrication, particularly when being laser cut make it one of the most cost effective plastics available especially for low quantity projects and prototype projects. We also fabricate higher grade Acrylics with improved thermal and dimensional properties including MIL-PRF-5425, and MIL-PRF-8184.

Standard Plastics

Polyvinyl Chloride (PVC) is a rigid, durable thermoplastic widely used for its excellent chemical resistance, low cost, and ease of fabrication. Naturally flame-retardant and self-extinguishing, PVC is well-suited for environments where corrosion, moisture, or flammability are concerns. It offers good dimensional stability, low moisture absorption, and strong dielectric properties, making it ideal for industrial, construction, and electrical applications.

PVC is commonly used in ductwork, valve and fitting components, chemical processing equipment, enclosures, signage, and electrical insulation. It machines easily, can be solvent cemented or welded, and is often available in both Type I (rigid) and Type II (impact-modified) grades. While it has a lower heat resistance than some engineering plastics, its versatility and affordability make it a go-to material for a wide range of fabrication needs. PVC is most commonly recognized in its Tube form, and we can easily machine and modify PVC tube.

Acrylonitrile Butadiene Styrene (ABS) is a tough, impact-resistant thermoplastic known for its excellent balance of strength, rigidity, and machinability at a reasonable price. ABS is lightweight and offers good dimensional stability, making it a popular choice for both prototyping and production parts. It also has good chemical resistance to acids and alkalis, and can be easily bonded, machined, or thermoformed.

Common applications include housings, enclosures, panels, structural components, and automotive trim. ABS is often used in vacuum forming and 3D printing due to its ease of processing and clean finish. While not ideal for outdoor use without UV stabilization, certain grades are formulated for enhanced weatherability or flame retardancy.

Polyethylene (PE) is a widely used thermoplastic known for its excellent chemical resistance, low moisture absorption, and outstanding impact strength. It has a naturally waxy, low-friction surface that resists sticking and abrasion, making it ideal for applications where sliding contact or chemical exposure is a factor. Polyethylene is available in several grades, including LDPE (Low-Density), HDPE (High-Density), and UHMW (Ultra-High Molecular Weight), each offering different balances of stiffness, strength, and wear resistance.

Polyethylene is probably most commonly recognized for its use in cutting boards, but they are also used for wear strips, chute liners, tanks, packaging components, and fluid handling parts. UHMW grades are especially valued in high-wear industrial environments due to their extreme toughness and low coefficient of friction. While PE cannot be easily bonded with adhesives, it is easily fabricated, welded, and machined.