Insulating Materials

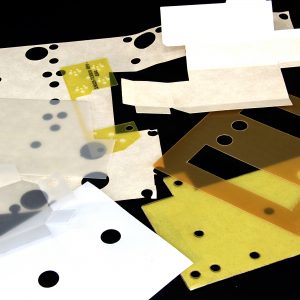

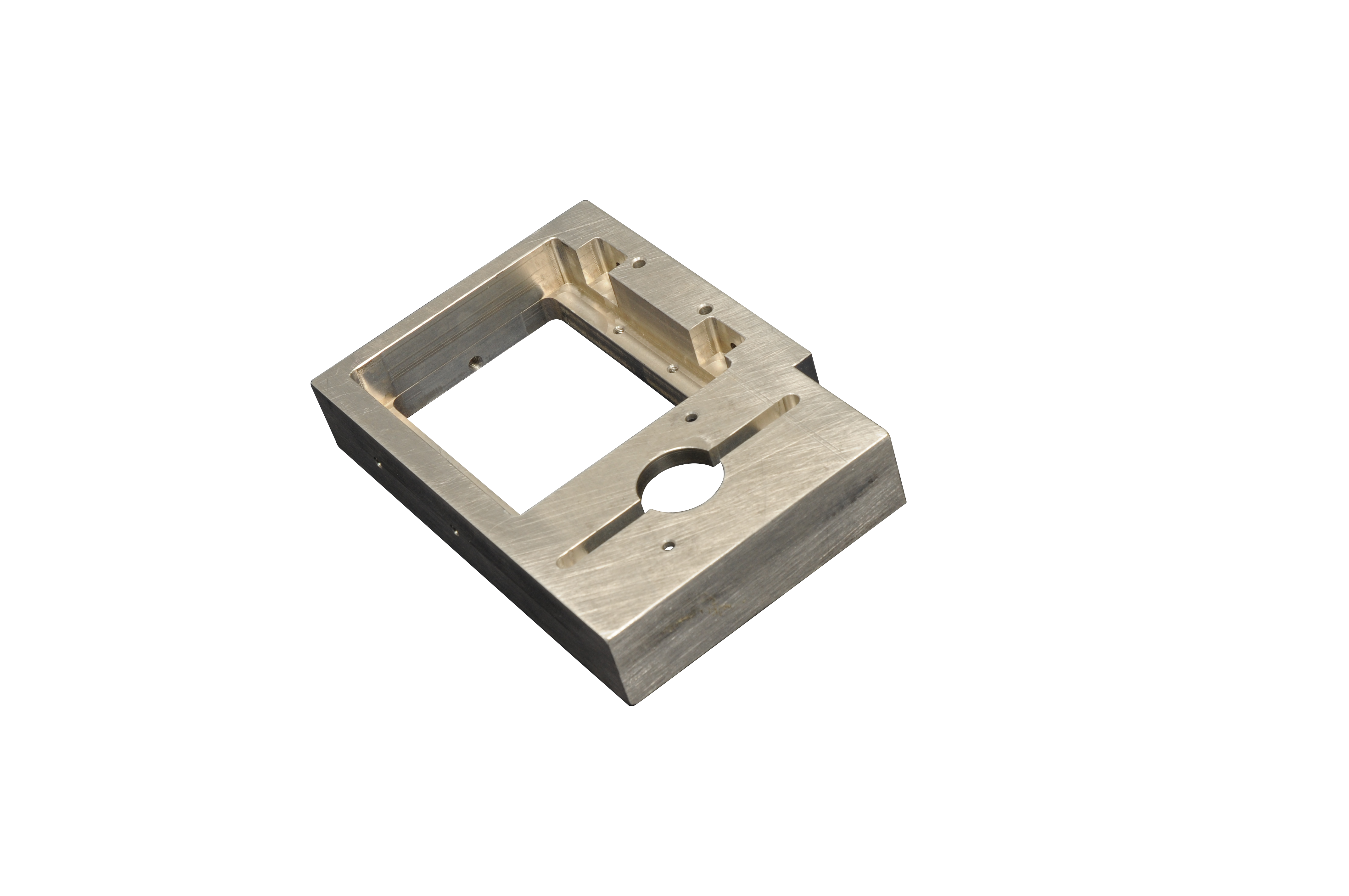

There are no shortage of options when it comes to selecting electrical of thermal insulating materials. While these materials vary in properties and performance they are critical to aerospace and electrical manufacturing. The Howard J. Moore Company carries a wide variety of insulating papers, films and plastics. These materials can be easily die cut, stamped, laser cut, formed or machined in both production and prototype quantities. They can also be printed on, and adhesive backed as needed. Below are list of the most commonly used insulating materials, however please contact us if you have a specialty material you would be interested in us fabricating for your company.

Nomex (Data Sheet)

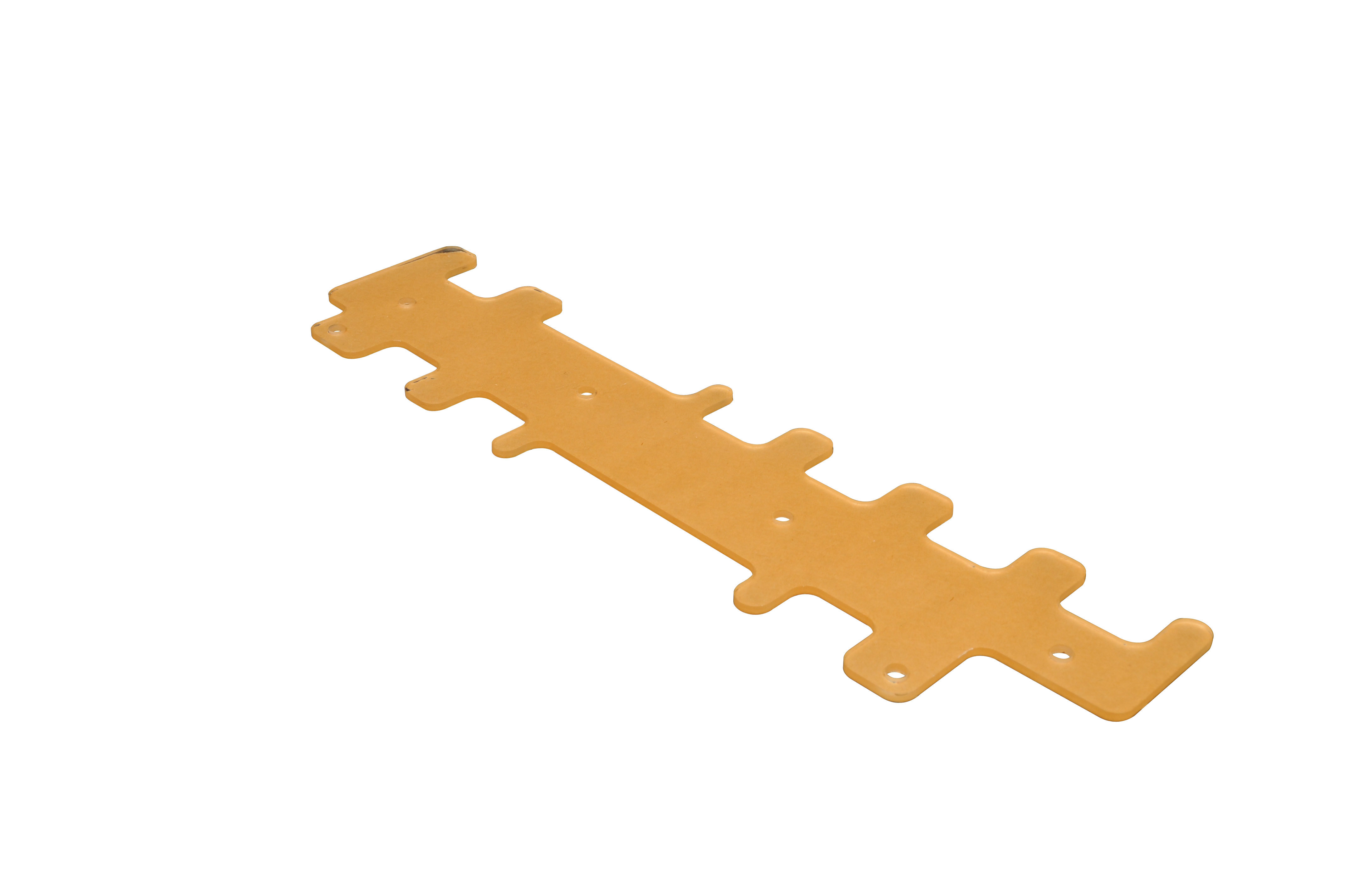

Nomex is a flame retardant paper product developed by DuPont. The material offers high dielectric strength, mechanical toughness, flexibility and resilience. We stock Nomex in thickness .002 up to .030” and is our most commonly used electrical insulator. The material is easy to cut, and can be bent or folded into more complex geometry depending on your needs.

Formex (Data Sheet)

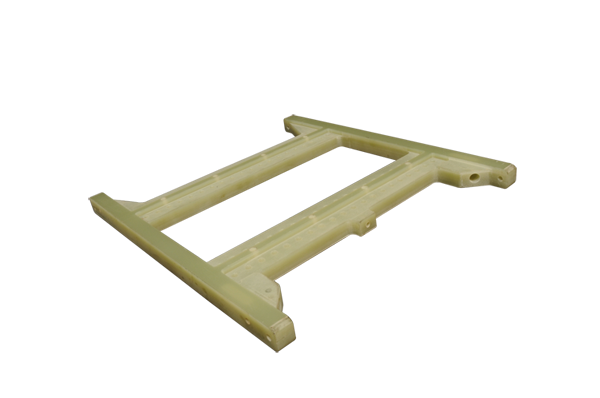

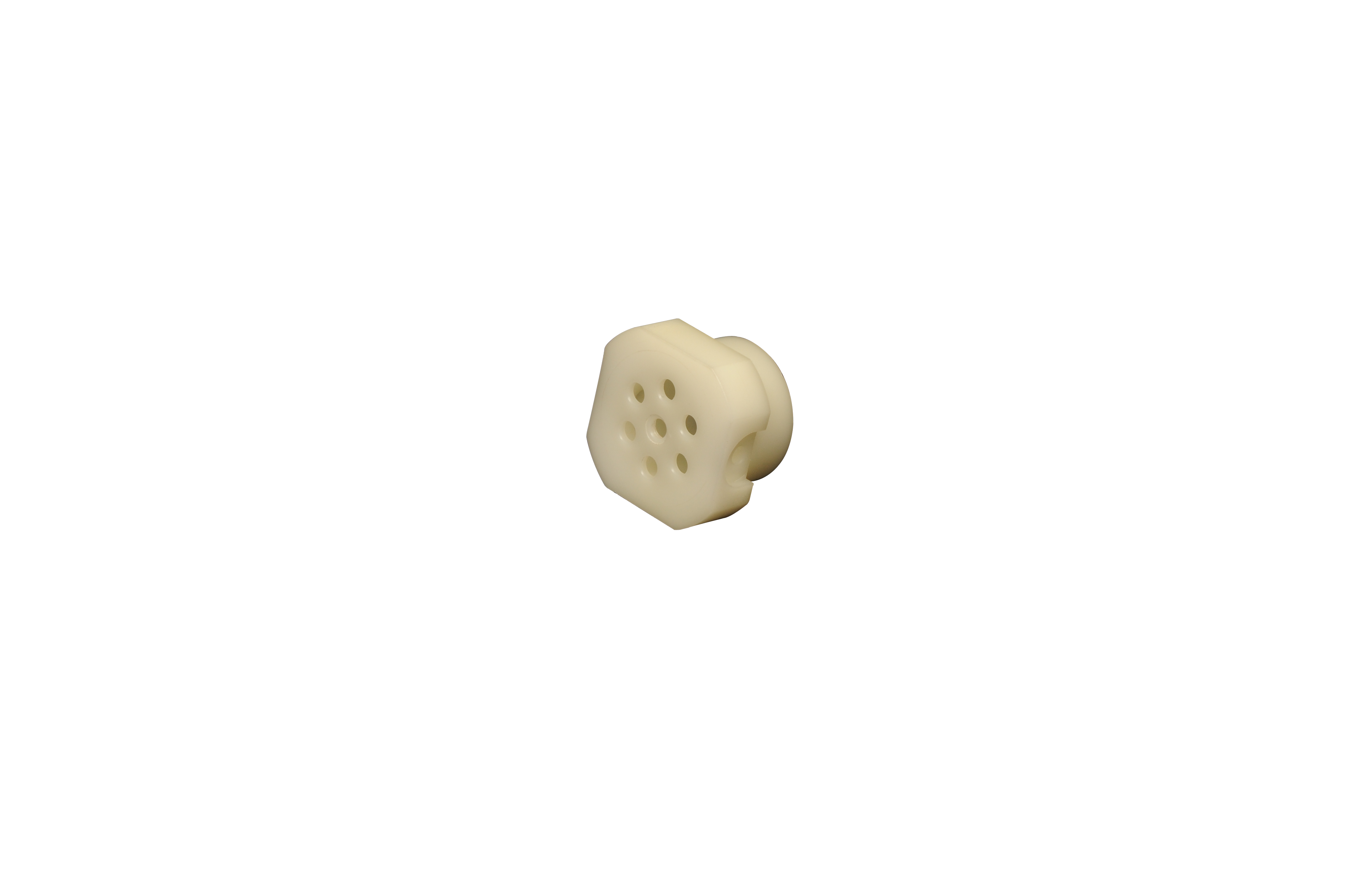

Formex™ GK, is a flame retardant polypropylene electrical insulation material from ITW Formex®. The material offers exceptional reliability and durability for a variety of industrial and consumer product applications. It offers superior dielectric strength, an elevated temperature rating, and exceptional moisture and chemical resistance to protect sensitive electronic elements from dielectric or environmental damage. It can also be used as a physical barrier that protects general users or service workers from the dangers of exposure to electrically charged components. In addition, Formex™ GK can easily be scored and folded into three-dimensional shapes, making it a highly versatile product. The Howard J. Moore Company carries Formex™ in thicknesses from .005” up to .062” thick and in both black and white. We can also add adhesive to the back of the material prior to fabrication.

Kapton (Data Sheet) (Spec Sheet)

DuPont™ Kapton® polyimide films have set the industry standard for over 45 years in high performance, reliability and durability, with a unique combination of electrical, thermal, chemical and mechanical properties that withstand extreme temperature, vibration and other demanding environments.

For applications requiring a high-performance all-polyimide film, Kapton® is the recommended choice due to its exceptional balance of properties over a wide temperature range. It has proven effective in extreme temperatures, ranging from -269°C to 400°C. This versatile film can be laminated, punched, formed, die cut or coated with adhesives.

Fishpaper

Vulcanized fiber, better known as fish paper is one of the original electrical insulators. The material has been in use for over 100 years. Fishpaper is made primarily from cotton or wood pulp that has been chemically treated to produce a dense, tough, and flexible electrical insulating material. Known for its excellent dielectric strength, arc resistance, and low moisture absorption, Fishpaper is widely used in electrical and electronic applications where lightweight, thin insulation is needed. Despite its name, it contains no actual fish—it earned its nickname from early uses in electrical wrapping and insulation.

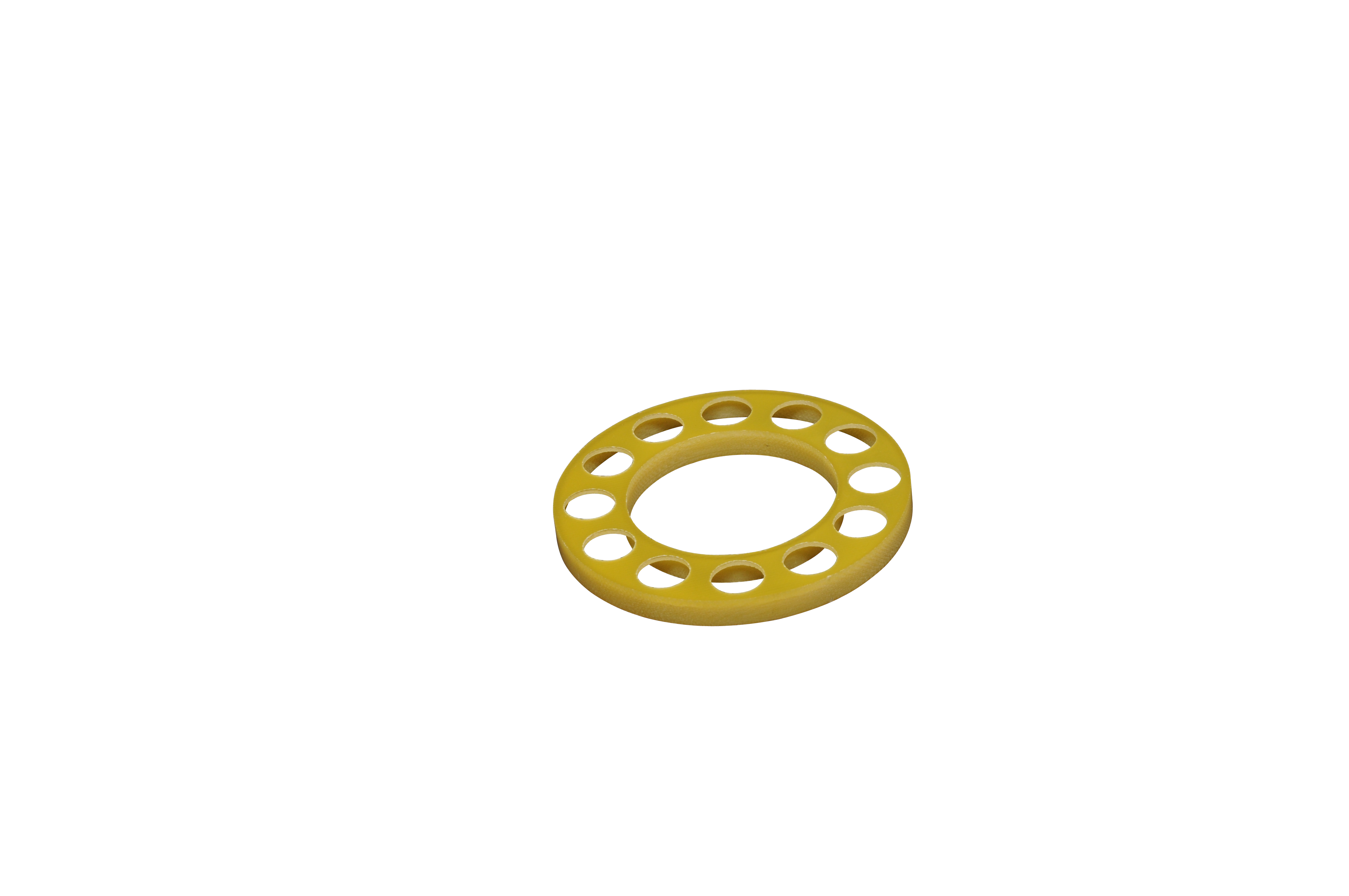

Fishpaper is easy to die cut, punch, and fold into complex shapes, making it ideal for slot liners, phase insulation, washers, gaskets, and spacers in motors, transformers, switchgear, and circuit breakers. Adhesive can be added to the back of Fishpaper prior to cutting to allow for ease of use during assembly. While it is not recommended for high-temperature applications, it performs well in dry environments and is cost-effective for low- to moderate-voltage insulation.

Mylar (Data Sheet) (Product Info)

Mylar is a polyester film made from polyethylene terephthalate (PET). Mylar’s strength and dimensional, and chemical stability over a wide temperature range, along with its low permeability, and good electrical properties make it a versatile material. Mylar also has the benefit of being available fully transparent as well as opaque. Mylar can easily be laminated to other materials or adhesives and is easy to die cut, stamp and form.

Mica (Spec Sheet)

Mica is a naturally occurring mineral used in the form of rigid or flexible insulating laminates for electrical and thermal insulation applications. Mica materials are manufactured by bonding thin sheets of mica paper—typically muscovite or phlogopite—with high-temperature-resistant resins such as silicone, epoxy, or shellac. The result is a durable, heat-resistant material with excellent dielectric strength, arc resistance, and thermal stability.

Mica is exceptionally well-suited for high-voltage, high-temperature, and arc-prone environments. It maintains its insulating properties at temperatures exceeding 1000°F (538°C), and some grades can perform even at 1800°F (982°C) intermittently. It is also resistant to moisture, flame, and many chemicals, making it ideal for use in electrical insulation for motors, transformers, heating elements, gaskets, furnace insulation, and aerospace or defense applications.Thinner sheets of Mica can be die cut up to .030” thick, the material is available in larger size sheet, rod and tube that we can machine into complex geometries. We can also add adhesive to the back of Mica Sheet prior to die cutting for easy application during assembly.