Phenolic Materials

Phenolic Laminates are a family of thermosetting plastic materials made by impregnating layers of paper, cotton fabric, or glass cloth with phenolic resin and curing them under heat and pressure. The result is a rigid, dense material with excellent mechanical strength, dimensional stability, and electrical insulation properties. Phenolics are among the oldest and most widely used industrial laminates, offering a cost-effective balance of performance, machinability, and durability.

Phenolic grades are classified based on their reinforcing substrate:

- Paper-based (e.g., XX, XXX) phenolics offer excellent electrical insulation and are used in low-voltage applications.

- Canvas (C) and Linen (L) fabric-based grades provide better mechanical strength and are used in structural and wear applications.

- Glass-reinforced phenolic (G3, G7, G10, G11, and GPO-3) offers superior heat resistance and dimensional stability, often used in high-performance electrical or thermal environments.

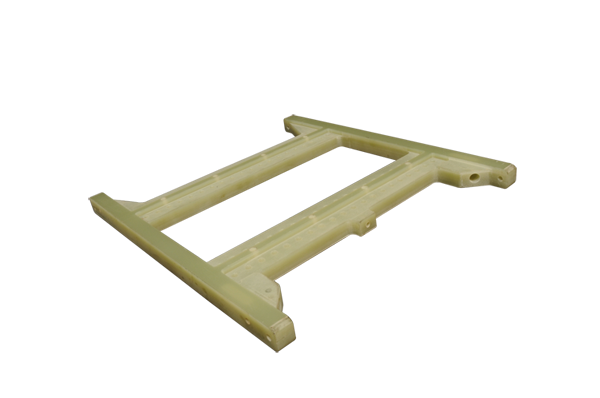

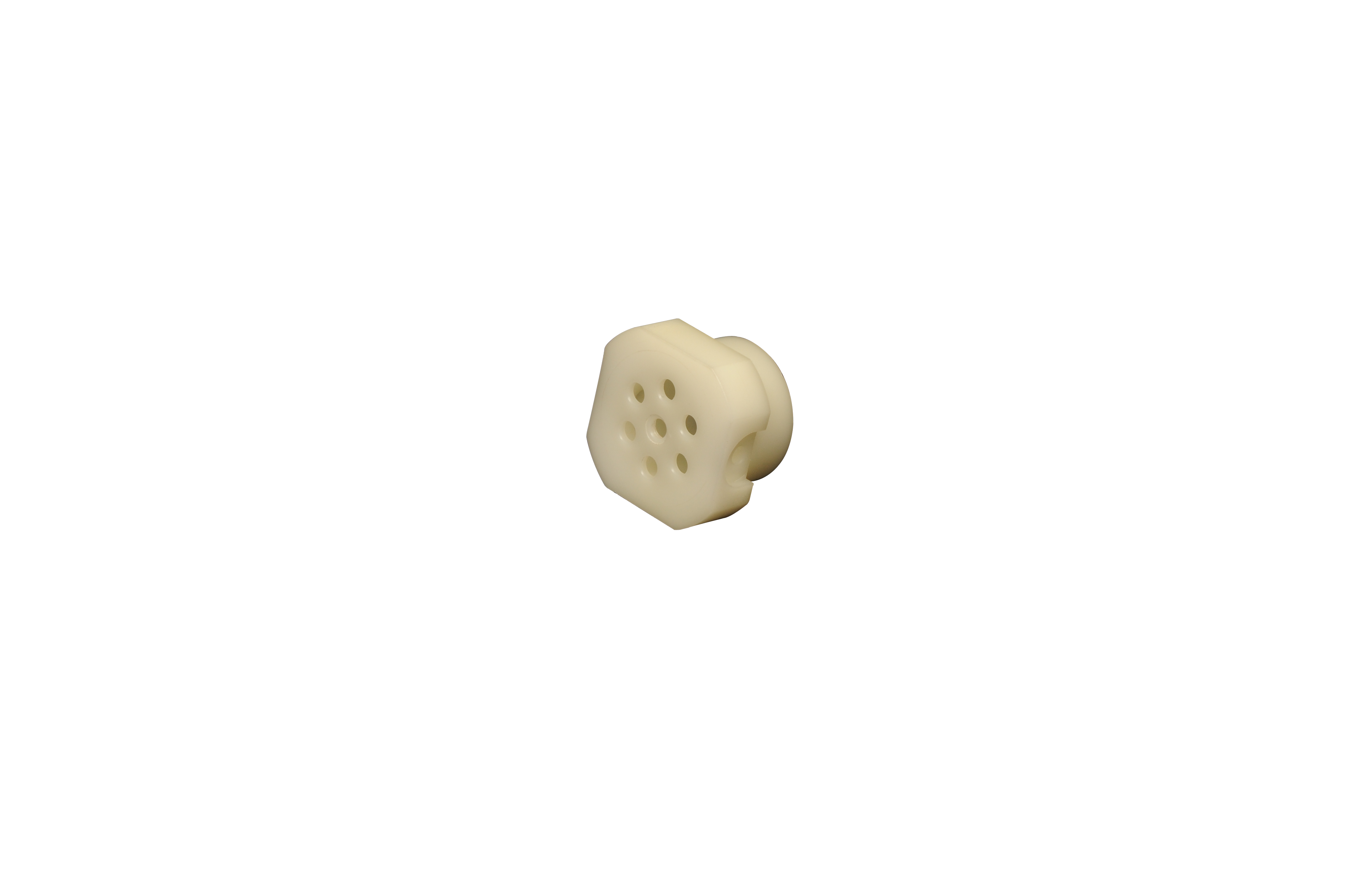

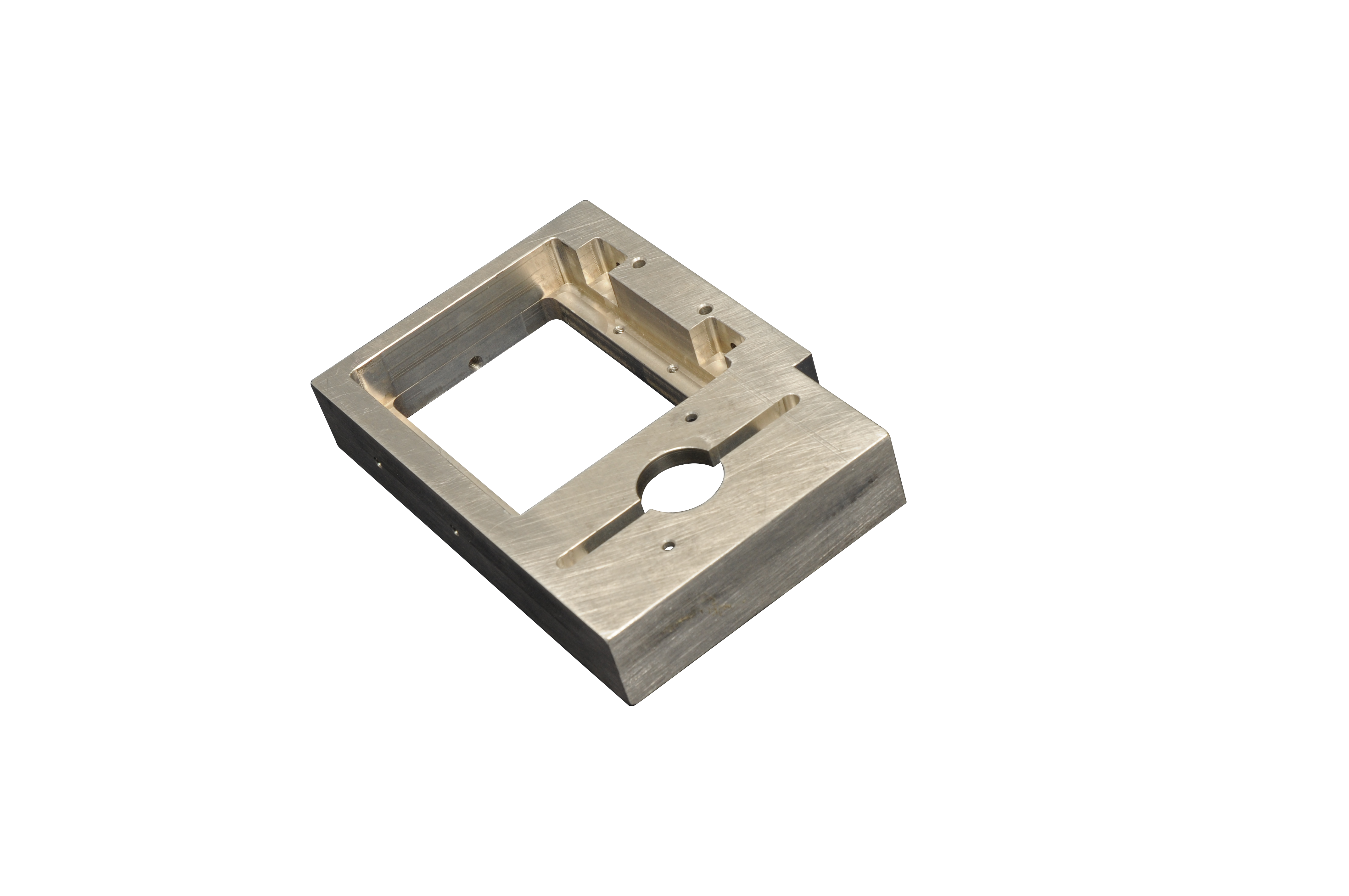

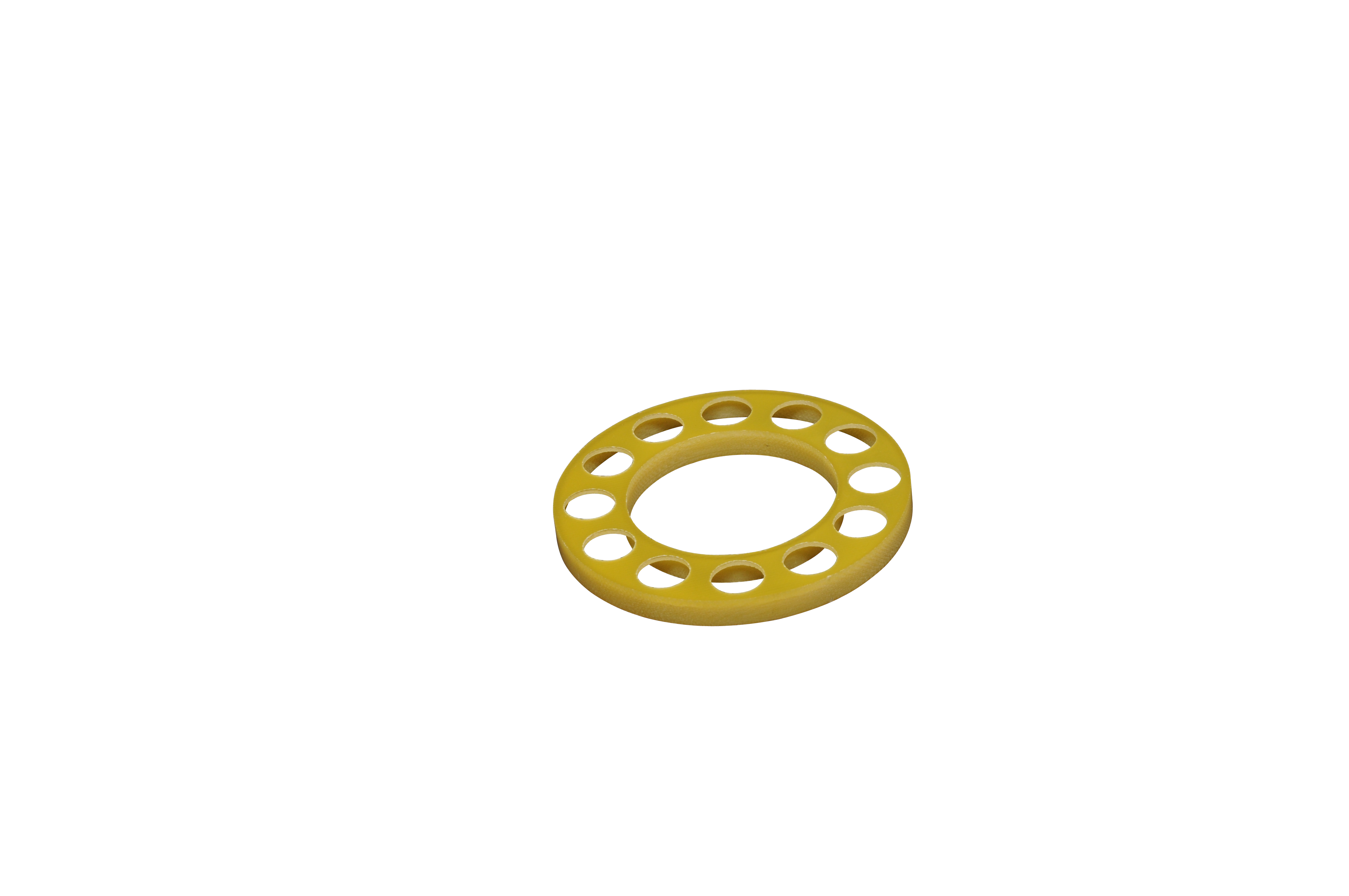

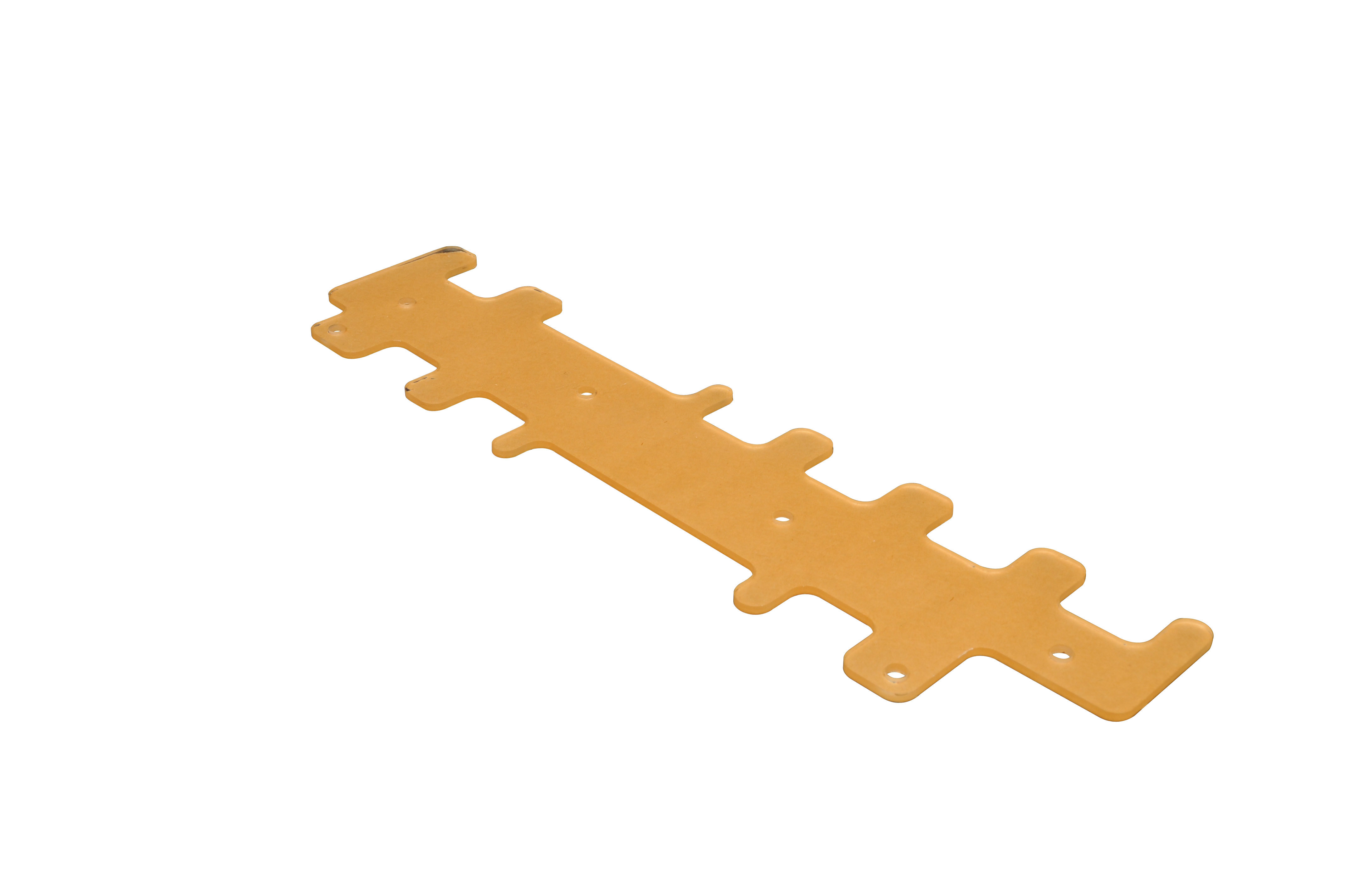

Phenolic materials are widely used in electrical switchgear, insulating bushings, terminal boards, mechanical spacers, wear pads, and structural brackets However the nature of Phenolic materials presents unique fabrication challenges. The use of substrate materials in the thermosetting process make the materials highly abrasive on tools and machinery and the layering of the material creates delamination risk. The Howard J. Moore Company has decades of experience fabricating phenolic materials and has the ability to machine and hold tight tolerances and complex geometries by using specialized tools, and work holding fixtures. Phenolic materials make up over a third of our total production volume, and we inventory most common grades of phenolics to allow for short lead times and quick turnaround.